Yesterday, our company's engineers went to Italy to help a client debug the protein bar production line.

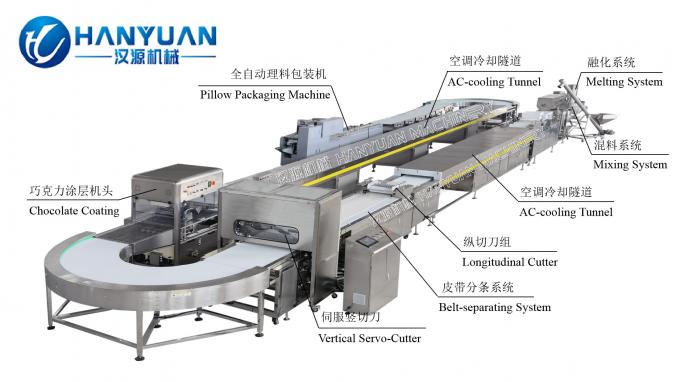

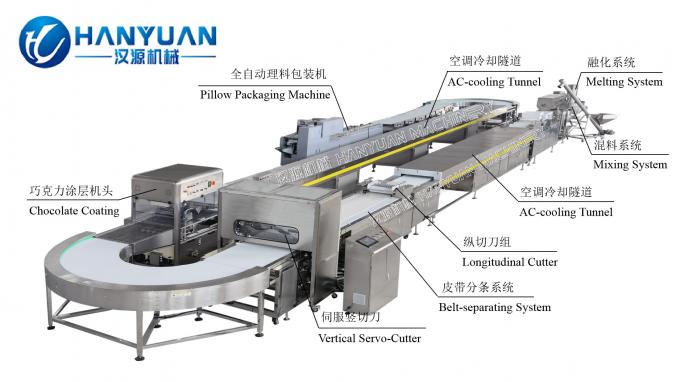

HANYUAN "Protein Bar Processing Line" is mainly applied in the industrial production of Granola Bar, Cereal Bar, Nuts Bar, Protein Bar,covering the melting of adhesive material, mixing of dry&adhesive materials, feeding&forming&fan-cooling&cutting, pillow inner packaging. This production line can realize the melting&insulation&quantitative discharging of adhesive materials. This production line adopts three-axle-hopper to realize the feeding and section of rectangular-shape or U-shape. This production line adopts fan cooling to cool the bar slab, which is suitable for the graininess bar. This production line adopts longitudinal-transverse-cutting knives to cut the slab into bas fastly. This production line adopts fully automatic pillow packaging , adding alining-dam-board and separating-rollers for fast sorting of bars, high-speeding packaging.

Debugging purpose

1.Verify the stability of equipment installation and interlocking operation

2. Test whether the production process parameters meet the standards

3. Confirm that all product indicators meet the customer's requirements

4. Train the customer's operators to master the use of the equipment

Preparations Before Debugging

1. Equipment inspection

♦Confirm that the individual machine debugging of the mixer, extruder, molding machine, cooling line, packaging machine, etc. has been completed.

♦Check that the circuit, airway and lubrication system are operating normally.

♦Calibrate sensors such as temperature, pressure and speed.

2. Raw material preparation

♦The raw materials such as protein powder, maltitol and crushed nuts meet the standards.

♦Prepare food-grade mold release agents, packaging films and other auxiliary materials.

3. Personnel arrangement

♦The equipment operators are in place.

♦The quality inspection personnel are preparing to take samples.

Debugging Process

Core process route

Raw material pretreatment → mixing → molding → cooling → cutting → packaging.

Detailed explanation of key processes

1. Raw material preparation

♦Protein powder, grains, etc. need to be sieved to prevent caking.

♦Syrups need to be preheated to 40-50℃ (to improve fluidity).

2 Mix

♦Use a planetary mixer/screw mixer to dry mix the materials first and then wet them.

♦Control the mixing time (usually 3 to 5 minutes) to avoid overstirring which may cause protein denaturation.

3. Cut into blocks and shape

Die pressing forming: After being pressed into sheet by a roller press, it is cut.

4. Cooling

♦The temperature is reduced to ≤25℃ at the center through the cooling tunnel (10-15℃).

♦Prevent condensation after packaging.

5. Packaging

♦Automatic packaging machine (nitrogen-filled or vacuum packaging.

♦Heat sealing temperature control: usually 120-150℃.

Summary: The commissioning of the Italian protein bar production line this time was very successful and received high recognition from the customer. We look forward to long-term cooperation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!